Wheel Bolt Pattern is the measured diameter of an imaginary circle formed by the centers of the wheel studs or bolt holes. Common bolt patterns have 4, 5, 6, or 8 lug holes, while less common have 3, 7, or 10 lug bolt patterns.

Interchangeable Wheel / Bolt Pattern Chart for Cars, Trucks, Vans, SUVs, Motorhomes, RVs, ATVs, UTVs and Trailers

This cross reference database was created to help you easily find a particular vehicle bolt pattern, and to identify other vehicles with wheels that will fit yours.

Wheel Bolt Pattern by Make and Model

Vehicle Bolt Pattern Specifications In This Cross Reference:

3 Lug Bolt Patterns:

A 3 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (3) and the bolt circle measurement, the notional circle determined by the center position of the studs.

A 3 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (3) and the bolt circle measurement, the notional circle determined by the center position of the studs.

Learn more about wheel dimensions.

Bolt Pattern Torque Sequence / Specifications:

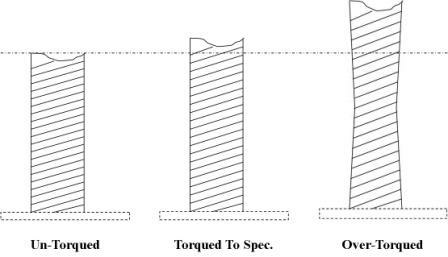

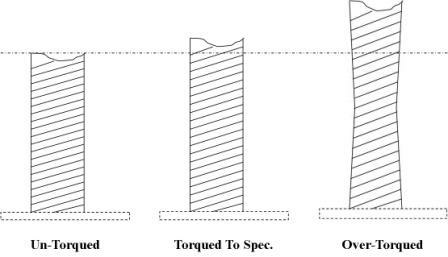

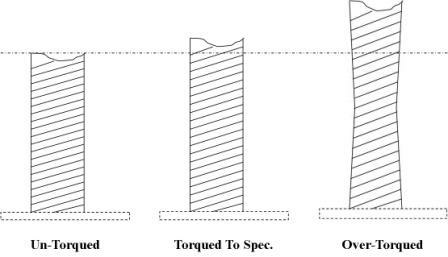

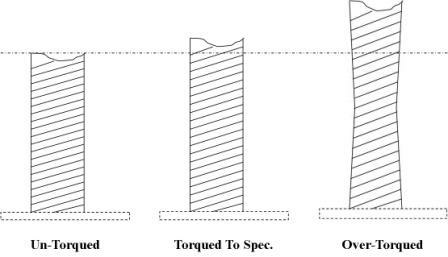

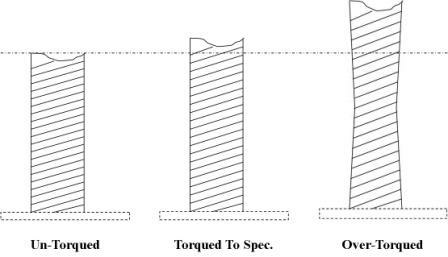

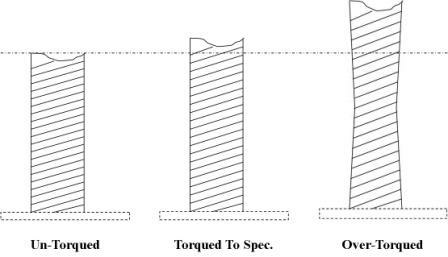

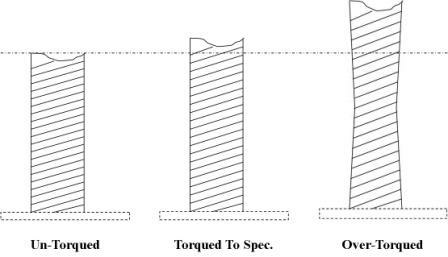

Note: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x 1.5 mm | 70 - 80 | 6.5 |

| 12 x 1.25 mm | 70 - 80 | 8 |

| 14 x 1.5 mm | 85 - 90 | 7.5 |

| 14 x 1.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | 8 |

| 1/2 in. | 75 - 85 | 8 |

| 9/16 in. | 135 - 145 | 8 |

It is prudent to re-torque wheels after about 60 to 90 miles (100km to 150km) of driving. Learn more about lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Wheel Bolt Patterns

Most recreational and utility trailers on the road today have a 4, 5 or 6 lug bolt pattern, while heavy-duty trailers will most often use 6, 8 or 10 lug wheels.

The most common trailer wheel bolt pattern overall is 5 X 4.5 and is also a very popular size in passenger cars.

Car makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 X 4.5 wheels, which also makes this a very popular bolt pattern in aftermarket wheels.

Other trailer bolt patterns are listed below, with links to vehicles with matching bolt pattern.

Small Trailer Wheel Bolt Patterns:

- 4 X 4 (most common)

- 4 X 9.44

Travel Trailer and Utility Trailer Wheel Bolt Patterns:

Heavy-Duty Trailer Wheel Bolt Patterns:

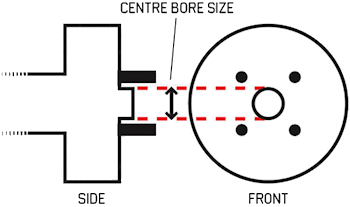

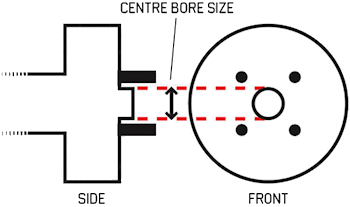

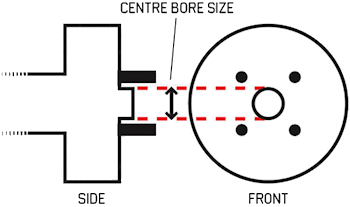

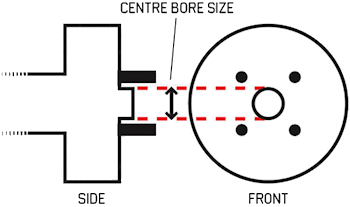

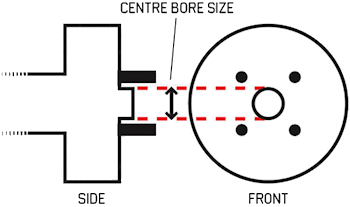

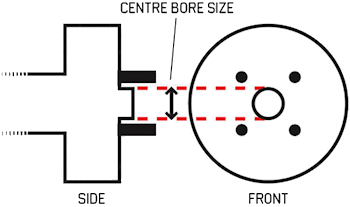

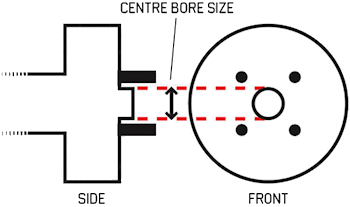

Wheel Hub Center Bore

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

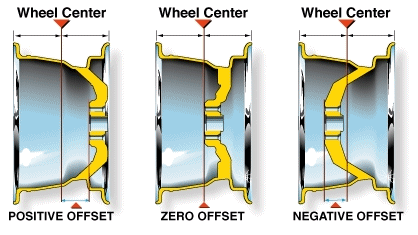

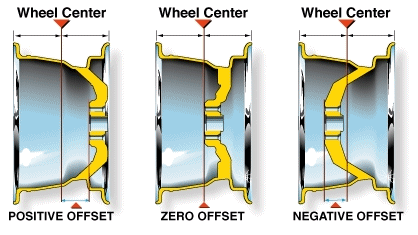

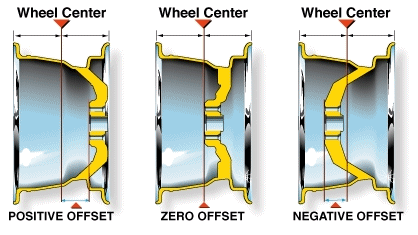

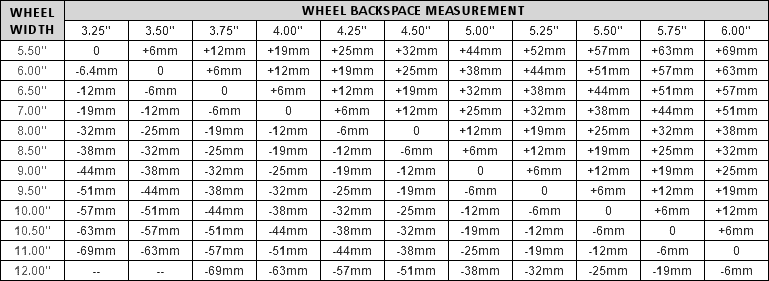

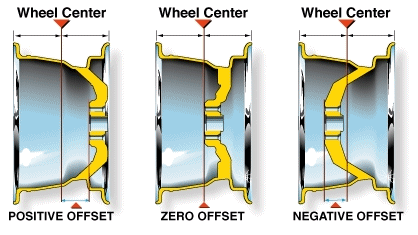

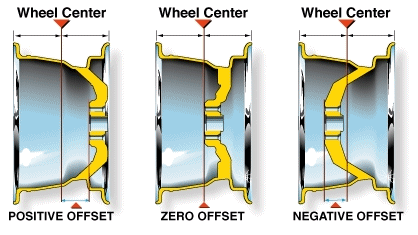

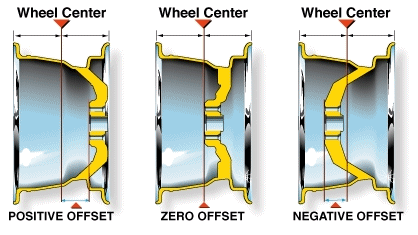

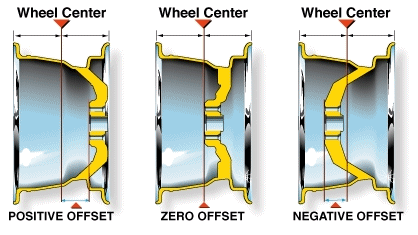

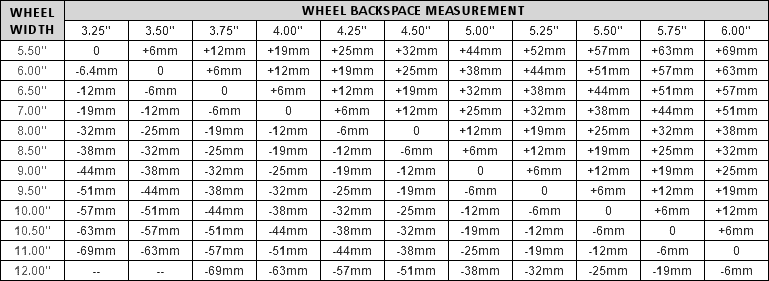

Wheel Offset

Wheel offset is the distance from the mounting surface of the wheel to the true center line of the rim. A positive offset means the mounting surface of the wheel is positioned in front of the true center line of the rim / tire assembly. This in effect brings the tire in to the fender well more. Conversely, a negative offset means the mounting surface of the wheel is behind the true center line of the rim / tire assembly. This will cause the tire to stick out away from the vehicle.

H = High - Positive Offset, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

M = Medium - Neutral Offset, typically RWD (Rear Wheel Drive) +20 offset

L = Low - Zero to Negative Offset, Offset typically RWD (Rear Wheel Drive) 0 offset

4 Lug Bolt Patterns:

- 4 X 85

- 4 X 90

- 4 X 98

- 4 X 100

- 4 X 108 (4 X 4.25)

- 4 X 110

- 4 X 112

- 4 X 115

- 4 X 130

- 4 X 137

- 4 X 140

- 4 X 143

- 4 X 144

- 4 X 150

- 4 X 156

- 4 X 166

- 4 X 3.75

- 4 X 4

- 4 X 4.25 (4 X 108)

- 4 X 4.5 (4 X 114.3)

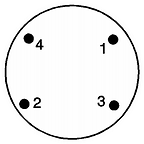

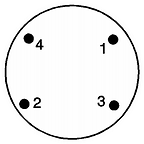

A 4 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (4) and the bolt circle measurement, the notional circle determined by the center position of the studs.

A 4 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (4) and the bolt circle measurement, the notional circle determined by the center position of the studs.

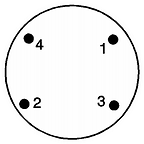

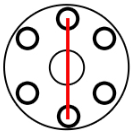

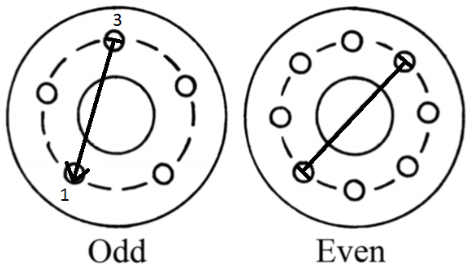

How To Measure 4 Lug Bolt Patterns

Measure 4 lug wheel bolt patterns from center to center distance between two studs that are across the hub from each other. This measurement is your bolt pattern diameter. Learn more about wheel dimensions.

Bolt Pattern Torque Sequence / Specifications:

Bolt Pattern Torque Sequence Specifications: 1, 3, 2, 4

Note: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x 1.5 mm | 70 - 80 | 6.5 |

| 12 x 1.25 mm | 70 - 80 | 8 |

| 14 x 1.5 mm | 85 - 90 | 7.5 |

| 14 x 1.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | 8 |

| 1/2 in. | 75 - 85 | 8 |

| 9/16 in. | 135 - 145 | 8 |

It is prudent to re-torque wheels after about 60 to 90 miles (100km to 150km) of driving. Learn more about lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Wheel Bolt Patterns

Most recreational and utility trailers on the road today have a 4, 5 or 6 lug bolt pattern, while heavy-duty trailers will most often use 6, 8 or 10 lug wheels.

The most common trailer wheel bolt pattern overall is 5 X 4.5 and is also a very popular size in passenger cars.

Car makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 X 4.5 wheels, which also makes this a very popular bolt pattern in aftermarket wheels.

Other trailer bolt patterns are listed below, with links to vehicles with matching bolt pattern.

Small Trailer Wheel Bolt Patterns:

- 4 X 4 (most common)

- 4 X 9.44

Travel Trailer and Utility Trailer Wheel Bolt Patterns:

Heavy-Duty Trailer Wheel Bolt Patterns:

Wheel Hub Center Bore

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Wheel Offset

Wheel offset is the distance from the mounting surface of the wheel to the true center line of the rim. A positive offset means the mounting surface of the wheel is positioned in front of the true center line of the rim / tire assembly. This in effect brings the tire in to the fender well more. Conversely, a negative offset means the mounting surface of the wheel is behind the true center line of the rim / tire assembly. This will cause the tire to stick out away from the vehicle.

H = High - Positive Offset, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

M = Medium - Neutral Offset, typically RWD (Rear Wheel Drive) +20 offset

L = Low - Zero to Negative Offset, Offset typically RWD (Rear Wheel Drive) 0 offset

5 Lug Bolt Patterns:

- 5 X 98

- 5 X 100

- 5 X 105

- 5 X 108 (5 X 4.25)

- 5 X 110

- 5 X 112

- 5 X 115

- 5 X 120

- 5 X 127 (5 X 5)

- 5 X 130

- 5 X 135

- 5 X 150

- 5 X 155

- 5 X 205

- 5 X 4

- 5 X 4.25 (5 X 108)

- 5 X 4.5 (5 X 114.3)

- 5 X 4.75

- 5 X 5 (5 X 127)

- 5 X 5.5

- 5 X 6.5

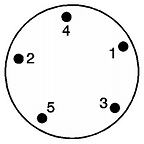

A 5 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (5) and the bolt circle measurement, the notional circle determined by the center position of the studs.

A 5 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (5) and the bolt circle measurement, the notional circle determined by the center position of the studs.

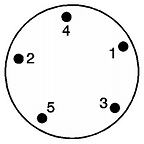

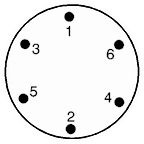

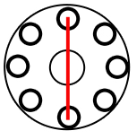

How To Measure 5 Lug Bolt Patterns

Measure 5 lug wheel bolt patterns from the outside edge to center distance between two studs that are across the hub from each other. This measurement is your bolt pattern diameter. Learn more about wheel dimensions.

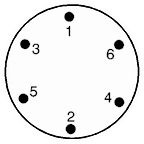

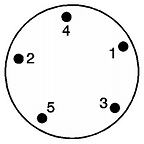

Bolt Pattern Torque Sequence / Specifications:

Bolt Pattern Torque Sequence Specifications: 1, 3, 5, 2, 4

Note: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x 1.5 mm | 70 - 80 | 6.5 |

| 12 x 1.25 mm | 70 - 80 | 8 |

| 14 x 1.5 mm | 85 - 90 | 7.5 |

| 14 x 1.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | 8 |

| 1/2 in. | 75 - 85 | 8 |

| 9/16 in. | 135 - 145 | 8 |

It is prudent to re-torque wheels after about 60 to 90 miles (100km to 150km) of driving. Learn more about lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Wheel Bolt Patterns

Most recreational and utility trailers on the road today have a 4, 5 or 6 lug bolt pattern, while heavy-duty trailers will most often use 6, 8 or 10 lug wheels.

The most common trailer wheel bolt pattern overall is 5 X 4.5 and is also a very popular size in passenger cars.

Car makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 X 4.5 wheels, which also makes this a very popular bolt pattern in aftermarket wheels.

Other trailer bolt patterns are listed below, with links to vehicles with matching bolt pattern.

Small Trailer Wheel Bolt Patterns:

- 4 X 4 (most common)

- 4 X 9.44

Travel Trailer and Utility Trailer Wheel Bolt Patterns:

Heavy-Duty Trailer Wheel Bolt Patterns:

Wheel Hub Center Bore

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Wheel Offset

Wheel offset is the distance from the mounting surface of the wheel to the true center line of the rim. A positive offset means the mounting surface of the wheel is positioned in front of the true center line of the rim / tire assembly. This in effect brings the tire in to the fender well more. Conversely, a negative offset means the mounting surface of the wheel is behind the true center line of the rim / tire assembly. This will cause the tire to stick out away from the vehicle.

H = High - Positive Offset, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

M = Medium - Neutral Offset, typically RWD (Rear Wheel Drive) +20 offset

L = Low - Zero to Negative Offset, Offset typically RWD (Rear Wheel Drive) 0 offset

6 Lug Bolt Patterns:

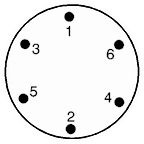

A 6 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (6) and the bolt circle measurement, the notional circle determined by the center position of the studs.

A 6 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (6) and the bolt circle measurement, the notional circle determined by the center position of the studs.

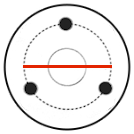

How To Measure 6 Lug Bolt Patterns

Measure 6 lug wheel bolt patterns from center to center distance between two studs that are across the hub from each other. This measurement is your bolt pattern diameter. Learn more about wheel dimensions.

Bolt Pattern Torque Sequence / Specifications:

Bolt Pattern Torque Sequence Specifications: 1, 6, 4, 2, 5, 3

Note: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x 1.5 mm | 70 - 80 | 6.5 |

| 12 x 1.25 mm | 70 - 80 | 8 |

| 14 x 1.5 mm | 85 - 90 | 7.5 |

| 14 x 1.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | 8 |

| 1/2 in. | 75 - 85 | 8 |

| 9/16 in. | 135 - 145 | 8 |

It is prudent to re-torque wheels after about 60 to 90 miles (100km to 150km) of driving. Learn more about lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Wheel Bolt Patterns

Most recreational and utility trailers on the road today have a 4, 5 or 6 lug bolt pattern, while heavy-duty trailers will most often use 6, 8 or 10 lug wheels.

The most common trailer wheel bolt pattern overall is 5 X 4.5 and is also a very popular size in passenger cars.

Car makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 X 4.5 wheels, which also makes this a very popular bolt pattern in aftermarket wheels.

Other trailer bolt patterns are listed below, with links to vehicles with matching bolt pattern.

Small Trailer Wheel Bolt Patterns:

- 4 X 4 (most common)

- 4 X 9.44

Travel Trailer and Utility Trailer Wheel Bolt Patterns:

Heavy-Duty Trailer Wheel Bolt Patterns:

Wheel Hub Center Bore

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Wheel Offset

Wheel offset is the distance from the mounting surface of the wheel to the true center line of the rim. A positive offset means the mounting surface of the wheel is positioned in front of the true center line of the rim / tire assembly. This in effect brings the tire in to the fender well more. Conversely, a negative offset means the mounting surface of the wheel is behind the true center line of the rim / tire assembly. This will cause the tire to stick out away from the vehicle.

H = High - Positive Offset, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

M = Medium - Neutral Offset, typically RWD (Rear Wheel Drive) +20 offset

L = Low - Zero to Negative Offset, Offset typically RWD (Rear Wheel Drive) 0 offset

7 Lug Bolt Pattern:

The 7 X 150 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (7) and the bolt circle measurement (150), the notional circle determined by the center position of the studs.

The 7 X 150 bolt pattern was only used by Ford. There are no other vehicles that use a 7 lug bolt pattern. The 7 Lug wheel option was part of Ford's HD Payload Package. Instead of measureing the bolt circle, simply count the lugs. Learn more about wheel dimensions.

Bolt Pattern Torque Sequence / Specifications:

Note: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x 1.5 mm | 70 - 80 | 6.5 |

| 12 x 1.25 mm | 70 - 80 | 8 |

| 14 x 1.5 mm | 85 - 90 | 7.5 |

| 14 x 1.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | 8 |

| 1/2 in. | 75 - 85 | 8 |

| 9/16 in. | 135 - 145 | 8 |

It is prudent to re-torque wheels after about 60 to 90 miles (100km to 150km) of driving. Learn more about lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Wheel Bolt Patterns

Most recreational and utility trailers on the road today have a 4, 5 or 6 lug bolt pattern, while heavy-duty trailers will most often use 6, 8 or 10 lug wheels.

The most common trailer wheel bolt pattern overall is 5 X 4.5 and is also a very popular size in passenger cars.

Car makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 X 4.5 wheels, which also makes this a very popular bolt pattern in aftermarket wheels.

Other trailer bolt patterns are listed below, with links to vehicles with matching bolt pattern.

Small Trailer Wheel Bolt Patterns:

- 4 X 4 (most common)

- 4 X 9.44

Travel Trailer and Utility Trailer Wheel Bolt Patterns:

Heavy-Duty Trailer Wheel Bolt Patterns:

Wheel Hub Center Bore

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Wheel Offset

Wheel offset is the distance from the mounting surface of the wheel to the true center line of the rim. A positive offset means the mounting surface of the wheel is positioned in front of the true center line of the rim / tire assembly. This in effect brings the tire in to the fender well more. Conversely, a negative offset means the mounting surface of the wheel is behind the true center line of the rim / tire assembly. This will cause the tire to stick out away from the vehicle.

H = High - Positive Offset, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

M = Medium - Neutral Offset, typically RWD (Rear Wheel Drive) +20 offset

L = Low - Zero to Negative Offset, Offset typically RWD (Rear Wheel Drive) 0 offset

8 Lug Bolt Patterns:

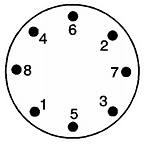

A 8 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (8) and the bolt circle measurement, the notional circle determined by the center position of the studs.

A 8 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (8) and the bolt circle measurement, the notional circle determined by the center position of the studs.

How To Measure 8 Lug Bolt Patterns

Measure 8 lug wheel bolt patterns from center to center distance between two studs that are across the hub from each other. This measurement is your bolt pattern diameter. Learn more about wheel dimensions.

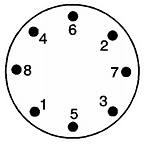

Bolt Pattern Torque Sequence / Specifications:

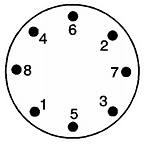

Bolt Pattern Torque Sequence Specifications: 1, 8, 4, 6, 2, 7, 3, 5

Note: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x 1.5 mm | 70 - 80 | 6.5 |

| 12 x 1.25 mm | 70 - 80 | 8 |

| 14 x 1.5 mm | 85 - 90 | 7.5 |

| 14 x 1.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | 8 |

| 1/2 in. | 75 - 85 | 8 |

| 9/16 in. | 135 - 145 | 8 |

It is prudent to re-torque wheels after about 60 to 90 miles (100km to 150km) of driving. Learn more about lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Wheel Bolt Patterns

Most recreational and utility trailers on the road today have a 4, 5 or 6 lug bolt pattern, while heavy-duty trailers will most often use 6, 8 or 10 lug wheels.

The most common trailer wheel bolt pattern overall is 5 X 4.5 and is also a very popular size in passenger cars.

Car makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 X 4.5 wheels, which also makes this a very popular bolt pattern in aftermarket wheels.

Other trailer bolt patterns are listed below, with links to vehicles with matching bolt pattern.

Small Trailer Wheel Bolt Patterns:

- 4 X 4 (most common)

- 4 X 9.44

Travel Trailer and Utility Trailer Wheel Bolt Patterns:

Heavy-Duty Trailer Wheel Bolt Patterns:

Wheel Hub Center Bore

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Wheel Offset

Wheel offset is the distance from the mounting surface of the wheel to the true center line of the rim. A positive offset means the mounting surface of the wheel is positioned in front of the true center line of the rim / tire assembly. This in effect brings the tire in to the fender well more. Conversely, a negative offset means the mounting surface of the wheel is behind the true center line of the rim / tire assembly. This will cause the tire to stick out away from the vehicle.

H = High - Positive Offset, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

M = Medium - Neutral Offset, typically RWD (Rear Wheel Drive) +20 offset

L = Low - Zero to Negative Offset, Offset typically RWD (Rear Wheel Drive) 0 offset

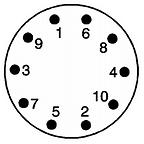

10 Lug Bolt Patterns:

A 10 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (10) and the bolt circle measurement, the notional circle determined by the center position of the studs.

A 10 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count (10) and the bolt circle measurement, the notional circle determined by the center position of the studs.

How To Measure 10 Lug Bolt Patterns

Measure 10 lug wheel bolt patterns from center to center distance between two studs that are across the hub from each other. This measurement is your bolt pattern diameter. Learn more about wheel dimensions.

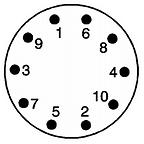

Bolt Pattern Torque Sequence / Specifications:

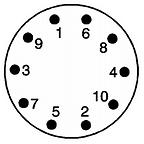

Bolt Pattern Torque Sequence Specifications: 1, 6, 8, 4, 10, 2, 5, 7, 3, 9

Note: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x 1.5 mm | 70 - 80 | 6.5 |

| 12 x 1.25 mm | 70 - 80 | 8 |

| 14 x 1.5 mm | 85 - 90 | 7.5 |

| 14 x 1.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | 8 |

| 1/2 in. | 75 - 85 | 8 |

| 9/16 in. | 135 - 145 | 8 |

It is prudent to re-torque wheels after about 60 to 90 miles (100km to 150km) of driving. Learn more about lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Wheel Bolt Patterns

Most recreational and utility trailers on the road today have a 4, 5 or 6 lug bolt pattern, while heavy-duty trailers will most often use 6, 8 or 10 lug wheels.

The most common trailer wheel bolt pattern overall is 5 X 4.5 and is also a very popular size in passenger cars.

Car makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 X 4.5 wheels, which also makes this a very popular bolt pattern in aftermarket wheels.

Other trailer bolt patterns are listed below, with links to vehicles with matching bolt pattern.

Small Trailer Wheel Bolt Patterns:

- 4 X 4 (most common)

- 4 X 9.44

Travel Trailer and Utility Trailer Wheel Bolt Patterns:

Heavy-Duty Trailer Wheel Bolt Patterns:

Wheel Hub Center Bore

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Wheel Offset

Wheel offset is the distance from the mounting surface of the wheel to the true center line of the rim. A positive offset means the mounting surface of the wheel is positioned in front of the true center line of the rim / tire assembly. This in effect brings the tire in to the fender well more. Conversely, a negative offset means the mounting surface of the wheel is behind the true center line of the rim / tire assembly. This will cause the tire to stick out away from the vehicle.

H = High - Positive Offset, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

M = Medium - Neutral Offset, typically RWD (Rear Wheel Drive) +20 offset

L = Low - Zero to Negative Offset, Offset typically RWD (Rear Wheel Drive) 0 offset

Jump to Manufacturer Bolt Patterns and Wheel Sizes

ATV / UTV / Power Sport Bolt Patterns:

Passenger Car / Truck Bolt Patterns:

RV / Bus / Commercial Truck Bolt Patterns:

Browse Wheels by Rim Size (Bolt Pattern, Diameter, Width)

How To Measure Wheel Bolt Pattern

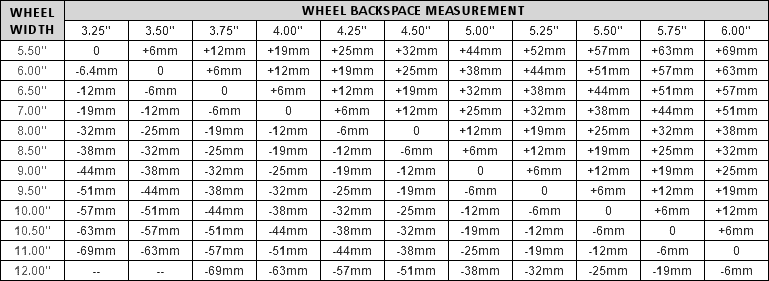

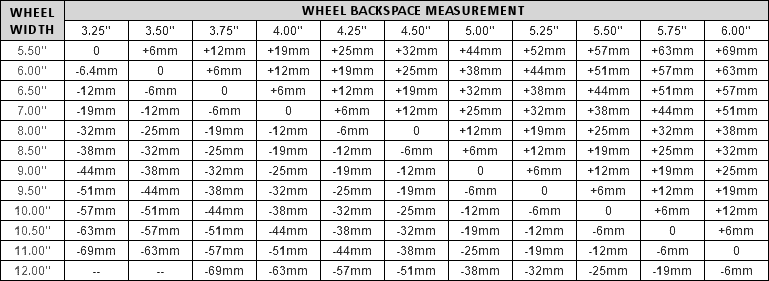

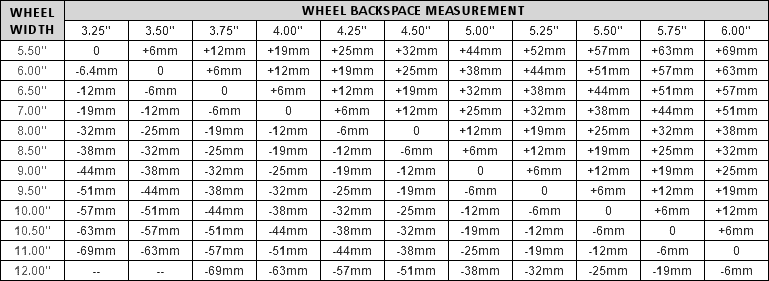

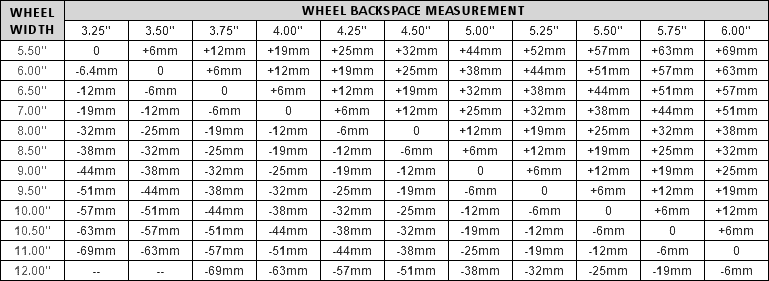

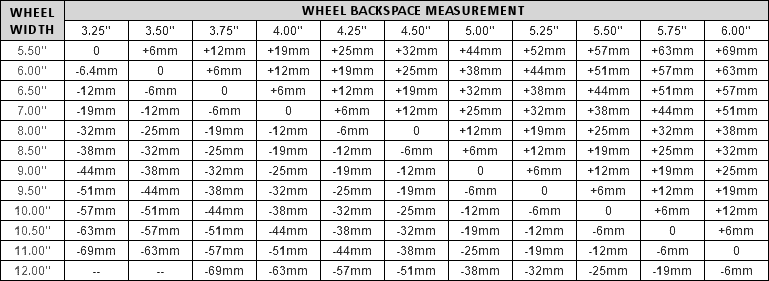

How To Measure Wheel Back Spacing / Offset

How To Re-Drill Axles/Brakes For Different Bolt Pattern Wheels

How To Plus Size Wheels and Tires

How To Properly Torque Lug Nuts / Lug Bolts

How To Determine The Age Of Your Tires

Tire Size Guide: Radials, Poly/Fibers, Bias-Ply's, Cheater and Dragster Slicks

Tire Size? How To Read A Tire Sidewall

Additional Wheel / Measurement Information

Key Identifying Wheel Dimensions: Wheel Bolt or Lug Pattern (or bolt circle, lug circle, lug pattern, etc.) is the measured diameter of an imaginary circle formed by the centers of the wheel lugs or bolt holes. Bolt patterns can be 3, 4, 5, 6, 7, 8 or 10 lug holes. A bolt circle of 5 x 4.5 would indicate a 5 lug bolt pattern on a circle with a diameter of 4.5 inches.

Key Identifying Wheel Dimensions: Wheel Bolt or Lug Pattern (or bolt circle, lug circle, lug pattern, etc.) is the measured diameter of an imaginary circle formed by the centers of the wheel lugs or bolt holes. Bolt patterns can be 3, 4, 5, 6, 7, 8 or 10 lug holes. A bolt circle of 5 x 4.5 would indicate a 5 lug bolt pattern on a circle with a diameter of 4.5 inches.

Wheel Dimensions

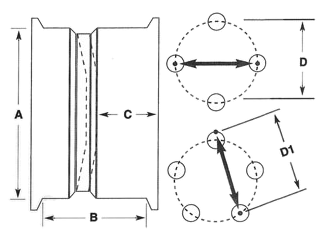

There are four important measurements that are used to categorize and identify a wheel for fitment purposes.

- Rim Diameter The actual diameter of the wheel at the point where the tire bead seats (NOT the outer lip of the rim).

- Rim Width Measure from the inside of the outer lip at the bead seating point to the inner lip.

- Back Spacing From the inside of the wheel at the point where it contacts the hub, brake drum or axle flange to the inside edge (lip) of the wheel.

- Bolt Pattern The measured diameter of an imaginary circle formed by the centers of the wheel lugs or bolt holes.

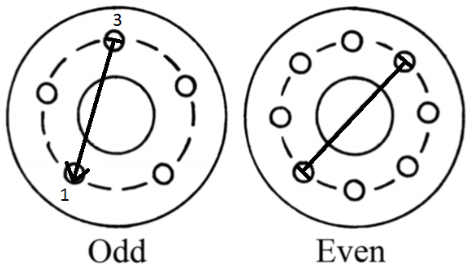

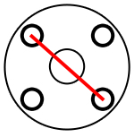

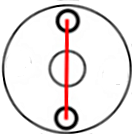

How To Measure Wheel Bolt Pattern

If there is an EVEN number of lugs: Measure center-to-center on lugs directly across from each other.

If there is an ODD number of lugs: Measure from the CENTER of one lug to the OUTER EDGE of the hole diagonally across from it.

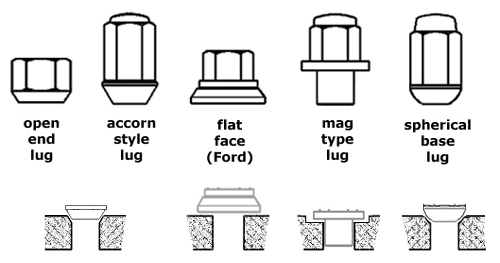

Lug Nut Types

Common Bolt Pattern Conversions

See Also:

- How to Measure Bolt Pattern Bolt pattern - diameter of an imaginary circle formed by the centers of the wheel lugs.

- Wheel Lug Nut / Bolt Torque Sequence Correct Wheel Lug Nut / Bolt Torque Sequence - 4 lug, 5 lug, 6 lug.

- How to Measure Wheel Back Spacing This measurement is important to be sure you have proper wheel clearance.

- How To Read A Tire Sidewall Learn to understand the common markings found on tire sidewalls.

- How To Plus Size Your Wheels

- Wheel, Tire and Fender Fitment Calculator Calculate Wheel Fitment, Tire Stretch and Rolling Radius. includes Speedometer Error Calculator. Play with specs, try different settings and combinations, compare results.

- Tire Size Change / Speedometer Calibration Calculator This calculator is designed to give information related to tire size changes and the general impact they have on the calibration of a speedometer. It determines speedometer error and tire size information based on published and generally accepted tire dimensions as given by the standard US tire system (i.e. 205/45-ZR16). All calculations are based on the assumption of a new tire (as opposed to used) where the numbers on the tire accurately represent the dimensions.